In today’s industrial landscape, the Internet of Things (IoT) plays a pivotal role in the way we monitor and control machinery, processes, and systems. One humble technology that has had a wide impact is Power Over Ethernet (PoE), which fuses data and power into one cable. Decades before it was energized, Ethernet was first developed by Bob Metcalfe at the Xerox Palo Alto Research Center in 1973. It’s a simple computer network protocol that creates “frames” from data which include addresses for the source and destination. Modern wireless networks offer convenience (not to mention a necessary lifeline to your cell phone) but nothing beats Ethernet in speed or reliability. Over two decades later, PowerDsine was the first to place a power injector into an Ethernet cable. Five years after their first install, the Institute of Electrical and Electronic Engineers (IEEE) formed an international standard to facilitate PoE deployment. These standards define the delivery of safe power.1

The Power Behind the Data

Industrial IoT relies heavily on data collection and communication. Whether it’s monitoring Temperature and humidity in a manufacturing facility, keeping track of equipment performance in a remote oil rig, or ensuring optimal conditions in a greenhouse, data is the lifeblood of modern industry. Traditionally, deploying sensors and devices in these settings was a complex task. Each device required a dedicated power source, which often involved intricate wiring and added maintenance overhead. This is where PoE comes into play.

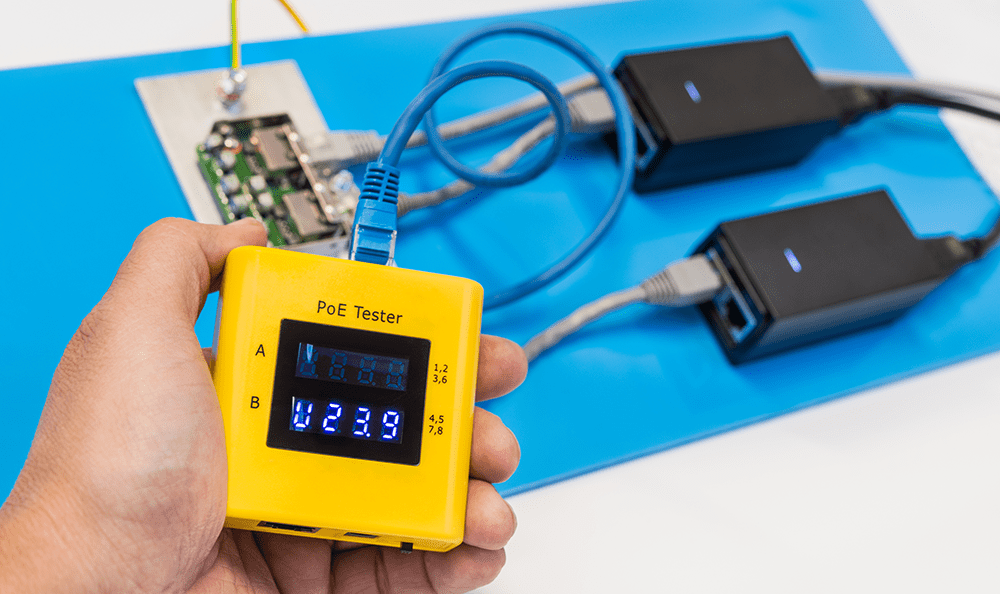

PoE allows both power and data to be transmitted over a single Ethernet cable, simplifying installation and reducing the need for additional power infrastructure. This technology has opened up new possibilities for industrial IoT by making it easier and more cost-effective to connect and power a wide range of devices.

PoE-enabled devices, such as the X-410™ and WebRelay™, are designed to seamlessly integrate into your existing Ethernet network. They offer a plug-and-play solution that simplifies deployment, reducing installation time and costs—no power supply necessary. Imagine being able to set up a network of sensors and controllers with minimal hassle, all powered and connected through a single cable!

Another key benefit of PoE is scalability. Our PoE solutions are scalable, allowing you to expand your network as your needs evolve. This flexibility is invaluable in industries where adaptability and rapid deployment are paramount.

Why PoE for Industrial IoT?

Let’s delve deeper into why Power Over Ethernet is a game-changer for IoT.

- Cost Efficiency. Traditional power and data cabling systems can be expensive to install and maintain. PoE eliminates the need for separate power cables, reducing infrastructure costs. This cost efficiency is particularly attractive for organizations looking to scale their IoT deployments without breaking the bank.

- Simplified Maintenance. Industrial environments can be harsh, and equipment often needs regular maintenance. With PoE, you can remotely power-cycle devices and troubleshoot issues without physically accessing each device. ControlByWeb’s products offer remote management capabilities, making maintenance a breeze.

- Energy Efficiency. Energy conservation is a growing concern for industries worldwide. PoE systems are designed to be energy-efficient, with power only delivered when needed. This not only reduces operational costs but also contributes to sustainability.

- Improved Data Accuracy. Reliable data is crucial in industrial IoT applications. PoE ensures a stable power supply, reducing the risk of data loss due to power disruptions. ControlByWeb’s PoE-enabled devices are known for their reliability, ensuring your data is accurate and up to date.

Real-World Applications

Here are a few real-world industrial scenarios to illustrate the practical applications of PoE:

- Factory Automation. In a manufacturing facility, PoE can power and connect sensors monitoring machine performance, temperature, and humidity. Our X-410™ can be used to collect and transmit this data to a central control system, enabling monitoring and predictive maintenance.

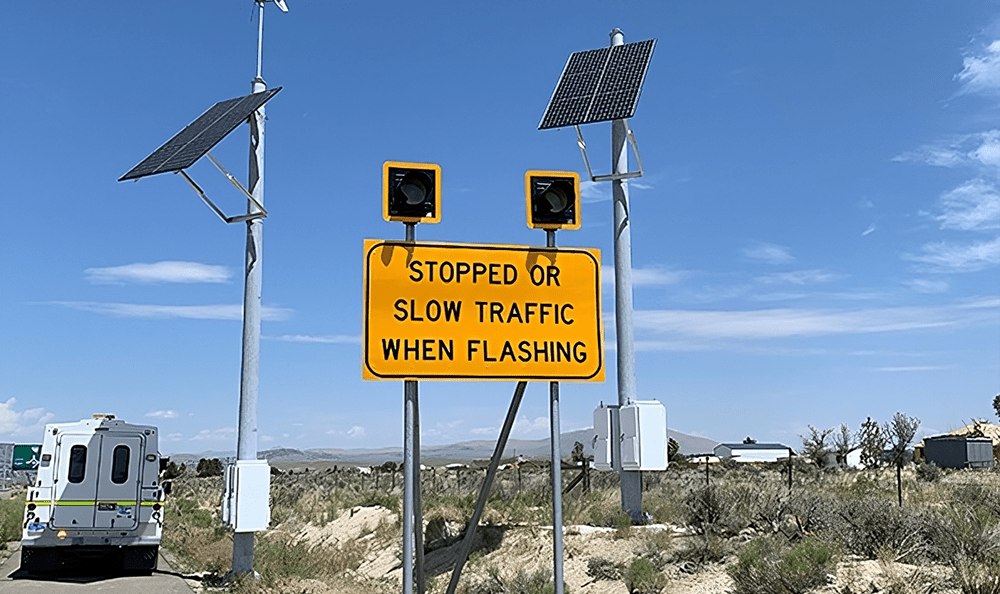

- Agriculture. In agriculture PoE can be employed to power and control irrigation systems, greenhouse climate control, and soil moisture sensors. With the right solutions, farmers can remotely adjust settings and optimize resource usage, leading to increased crop yields and cost savings.

- Oil and Gas. On remote oil rigs, PoE can power and connect surveillance cameras, security systems, and environmental sensors.

- It’s worth noting that some devices draw more power than a PoE can provide; the standard is limited to 30 W. Consult an expert before you buy.

The ControlByWeb Difference

Power Over Ethernet is a linchpin in IoT, revolutionizing the way industries monitor and control their processes. It offers cost efficiency, scalability, and reliability, making it an ideal choice for businesses across various sectors. If you’re ready to empower your industrial operations with the latest in IoT technology, consider ControlByWeb’s solutions.

For help with your industrial application, get in touch with our team or schedule a 15-minute demo to get a feel for our devices.