“In the twentieth century, computers were brains without senses—they only knew what we told them.”

‐ Kevin Ashton.

Interconnected electronic devices have existed since the 19th century, but the Internet of Things (IoT) as we know it wasn’t coined until 1999 by British Technologist Kevin Ashton. Ashton recognized the value of computers that could collect, store, and use data without human involvement.

Before IoT implementation became standard, early machine automation required a person to be involved in what’s known as a human-in-the-loop (HITL) system. A device can capture data, but it’s up to a person to respond. HITL systems are still in use for outcomes that require decision-making or involve ambiguous machine triggers.

In contrast to HITL systems, Internet of Things (IoT) devices work without input or output from a person, able to execute commands or log data dependent on predetermined conditions. These devices can also utilize peer-to-peer networking to “talk” with each other and send or receive commands. In the decades since its introduction, IoT has been common in just about every industrial setting and has shaped how people work.

IoT is Everywhere

There are hundreds (if not thousands) of industrial applications where smart I/O improves outcomes and reduces the need for human involvement. Many applications, like server room monitoring or HVAC control, apply across industries. Here are some industry-specific examples where automation

stands out:

Manufacturing. Anyone who’s seen an episode of How It’s Made understands the complexity of a manufacturing line. IoT devices can be used to improve production efficiency, quality control, and safety in factories. Machines can capture and use vast amounts of data that would be impossible for any person to parse through, and that’s especially true on the manufacturing floor.

Healthcare. Beyond building automation, hospitals turn to IoT to track medication adherence, monitor patients and medical equipment, provide remote care, monitor medical gas tanks, and analyze staff deployment. In the future, robotics powered by the Internet of Things could revolutionize treatment and testing.

Food & Beverage. Whether it’s adjusting the environment of a crop storage facility, monitoring the temperature and humidity of dozens of walk-in coolers at a stadium, or keeping a restaurant running smoothly, a lot goes into keeping perishables from perishing. Every step of the process, from the farm to the table, can benefit from IoT implementation.

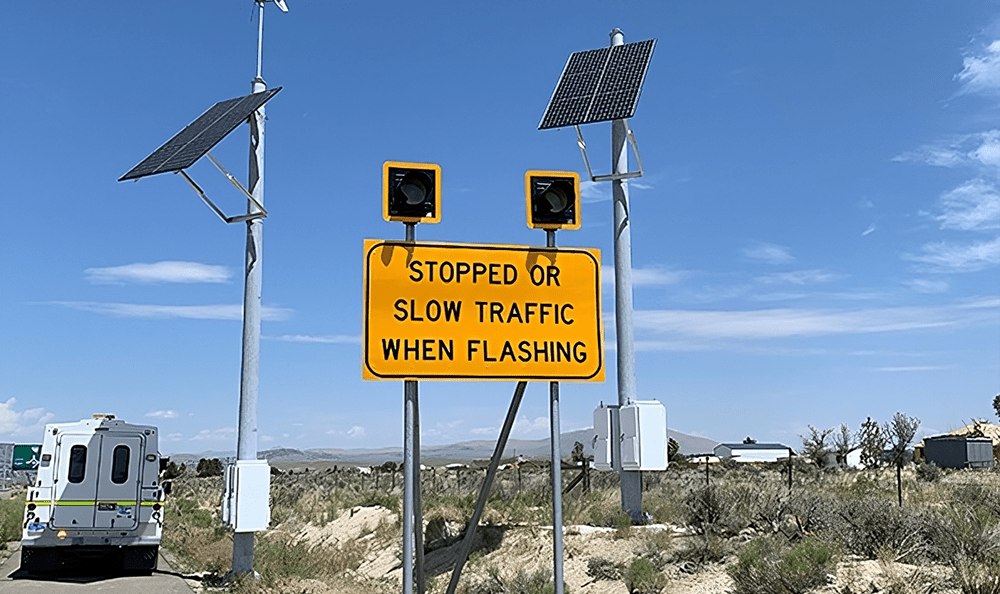

Transportation. Long gone are the days of police officers directing traffic through hand signals. Traffic stops, lighted road signs, gated parking lots, and toll roads can all be automated through remotely powered IoT devices. This makes transportation safer and more efficient—and removes the need for people to drive miles and miles to ensure their technology is working.

Water Management. Lift stations are the poster child of automation—IoT devices can be used for level measurement, VFD control, hour metering, remote data acquisition, pump condition monitoring and control, pump alternating, and alarm control. Learn more on our lift station application page.

Get In Touch

If you have a data-driven application, we have an I/O solution. Talk with our sales engineers to find the right fit for your needs.

The Benefits of IoT Implementation

The Internet of Things enables organizations to collect and analyze data in real-time in ways that weren’t possible before. Here are some of the broad benefits of IoT implementation:

- Improved efficiency and productivity: IoT can help businesses automate tasks, optimize processes, and reduce downtime, leading to significant improvements in efficiency and productivity. As in the walk-in cooler example above, IoT sensors can be used to monitor equipment performance and predict potential failures, allowing for proactive maintenance and preventing costly downtime.

- Enhanced decision-making: IoT devices generate vast amounts of data that can be analyzed to gain valuable insights into customer behavior, market trends, and operational performance. These insights can be used to make more informed decisions, improve resource allocation, and identify new business opportunities.

- Reduced costs: IoT can help organizations save money in a number of ways, such as by reducing energy consumption, improving inventory management, and optimizing logistics. For example, IoT-enabled smart buildings can automatically adjust lighting and HVAC settings to reduce energy costs.

- Increased safety and security: IoT can be used to monitor for hazards, detect security breaches, and provide real-time alerts. IoT sensors can be used to monitor air quality levels, detect unauthorized access to restricted areas, or remotely reboot IP cameras.

The ControlByWeb Difference

As IoT technology continues to develop and become more affordable, it is likely that we will see even more widespread adoption of IoT devices and solutions. But you don’t have to wait for the future to find affordable, flexible IoT solutions for your industrial application. For help with your industrial application, get in touch with our team or schedule a 15-minute demo to get a feel for our devices.