In the industrial Internet of Things (IIoT), there’s a device and technology to fill every niche. This is especially true for PLCs (programmable logic controllers). There’s a wide range of models that offer different features, processing power, and I/O capabilities. Generally, more robust controllers mean larger casing and a higher power draw.

There aren’t exactly size categories for PLCs. (You don’t go shopping for a medium or large like a sweater.) Still, some controllers are large and powerful, bringing endless connection points and speedy processors. They also carry an equally hefty price tag and limitations on where—and how—they’re installed. On the opposite end of the spectrum is the micro PLC. They may be more limited in function, but they’re smaller, more flexible, and more affordable. And they often run on more lightweight software or an embedded UI, which is the case for ControlByWeb micro PLCs.

See the differences between regular and micro PLCs and learn why the smaller option is an ideal choice for seamless automation solutions.

Understanding Micro PLCs vs. Regular PLCs

Micro PLCs, or micro programmable logic controllers, are compact and cost-effective automation devices that offer numerous advantages over traditional PLCs. While regular controllers are often built for larger-scale industrial applications with significant I/O needs, micro PLCs are specifically designed to excel in smaller automation projects that require less complex control systems. Here are the primary differences:

Compact & Efficient

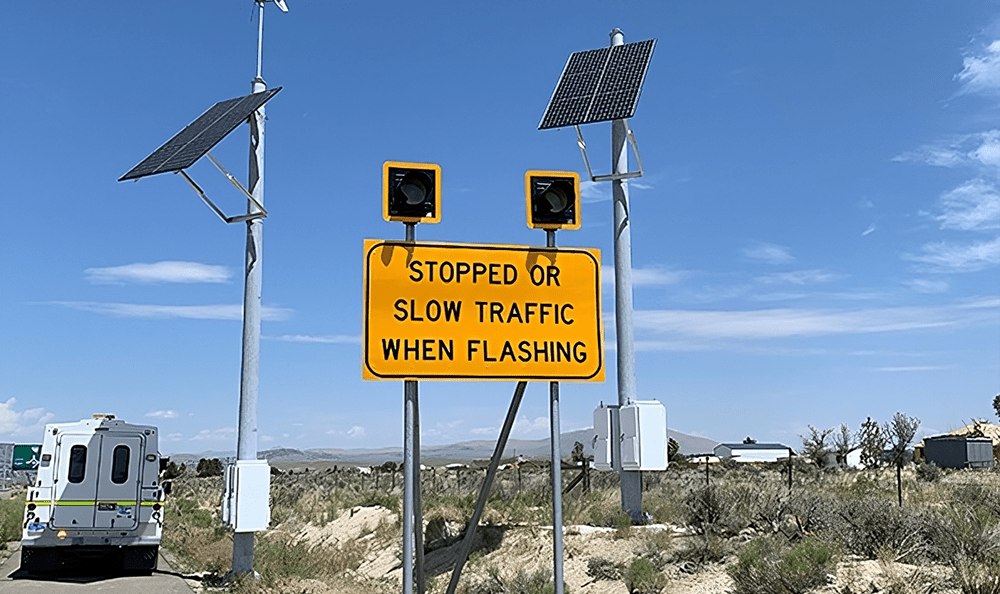

Micro PLCs are significantly smaller and more power efficient than regular controllers, making them ideal for space-constrained applications where size is a factor. A large PLC will fit the bill for avionics, factory lines, and offshore drilling rigs—but good luck getting one to fit into a solar-powered, offsite control box. Larger PLCs typically require higher voltage levels in the range of 110V to 240V AC. Micro PLCs, on the other hand, often work with 24V DC.

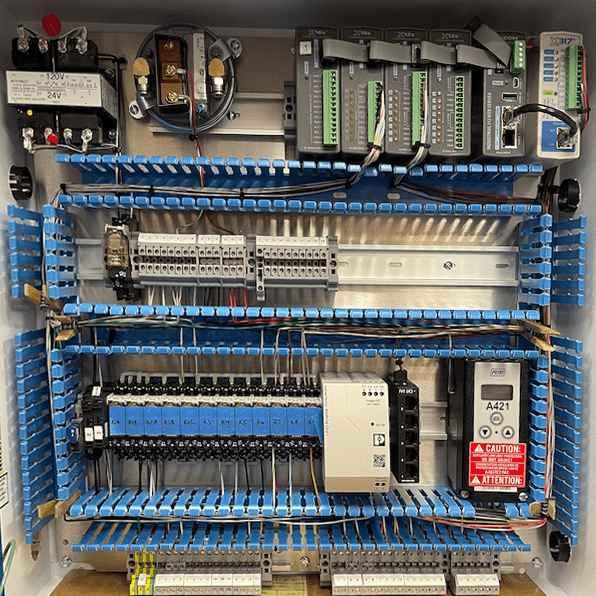

The compact size and less restrictive power requirements give micro PLCs a key advantage. The smaller devices have an easier time fitting in a small control panel or mobile application. Controllers like many of our 400 Series are compatible with Power Over Ethernet or standard 9-28VDC. Others can use batteries as the primary source of power or a backup. They are easy to mount on a DIN rail, secured in a control box, or embedded directly into machinery.

Despite their small size, Micro PLCs still offer a wide range of input and output options, allowing for the control of various devices and sensors. This makes them suitable for a wide range of applications, from simple automation tasks to more complex control systems.

Easier to Use

A micro PLC will often be simpler to set up, since there are less inputs, outputs, and other components. There may be features in a larger PLC that will need to be ignored or, worse, get in the way while tailoring it to a specific application.

One aspect that makes all the difference when installing and monitoring a controller of any size and capability is the interface and software. Unfortunately, it’s all too common for micro PLC manufacturers to burden their hardware with overly complicated software and user interfaces. They’ll often include the same UI as more complex controllers. This makes the experience more consistent across their device lineup but defeats the simplicity of a micro PLC. This is an area where ControlByWeb PLCs really stand out.

Our controllers use no-code programmable logic that allows you to set them up through drop-down menus—it doesn’t get any easier than that. Having a simplified UI saves time and allows additional users to make changes as necessary without being stonewalled by dense ladder logic. Customers are impressed with how easy it is to set up and use ControlByWeb PLCs.

“Easy to configure … solid customer support.”

“Easy to configure, solid documentation, solid customer support before and after purchase.”

Flexible & Scalable

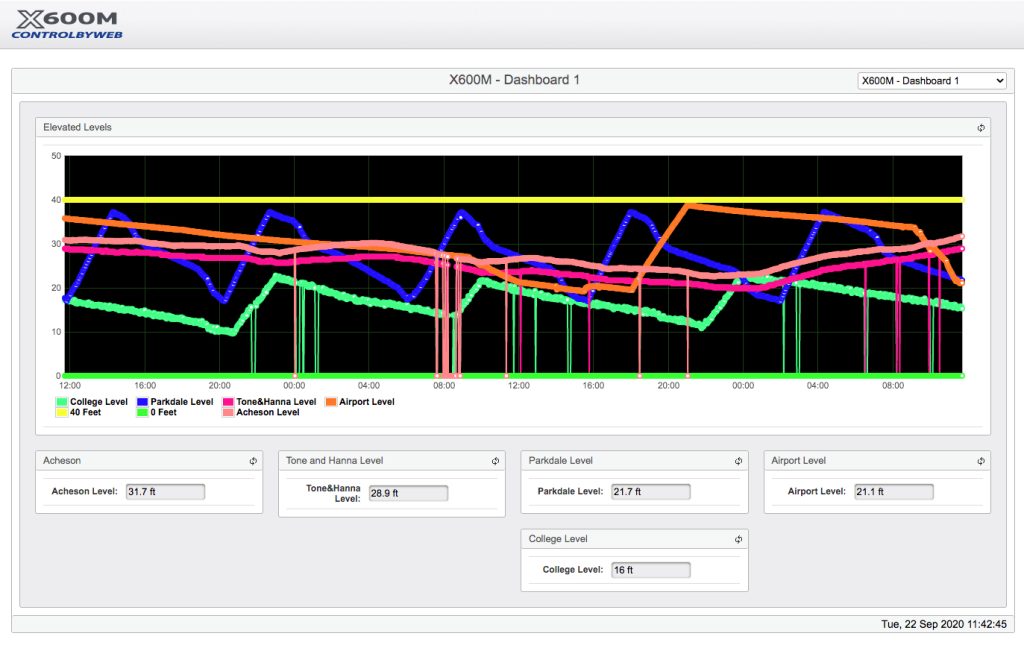

Micro PLCs can “power up” with modular capability, which allows additional controllers and relays to connect to the master unit. Peer-to-peer capability can even make that added I/O work wirelessly. This is ideal in settings where it would be difficult or impossible to hardwire the full application. The X-600M web-enabled I/O controller, an expandable PLC, can handle up to 64 I/O cards for a staggering 1,024 I/O points. (Not bad for what could be considered a micro PLC.)

Modular designs enable integrators to customize the control system without extensive rewriting or reprogramming, ensuring the system can easily accommodate future changes or expansions. And, while not unique to micro PLCs, having multi-protocol support allows a controller to work with a broader range of systems and SCADAs, sharing data with other automation devices or cloud-based platforms.

The scalability of micro PLCs is another key advantage. Users can start with a basic setup and gradually add more modules or features as their automation needs grow. This scalability makes micro PLCs a cost-effective solution, as users only need to invest in the necessary components at each stage of the system’s development.

Overall, the flexibility and scalability of Micro PLCs provide users with the freedom to adapt and expand their control systems as needed, ensuring long-term compatibility and cost efficiency.

More Affordable

With a micro PLC, you aren’t paying for features and I/O that you don’t need. They’re still plenty robust and a perfect fit for a broad range of applications even at a lower price. This is especially important for systems integrators who build all-in-one solutions at scale and have a shorter list of needed components and capabilities.

As needs change over time, it’s less expensive to add compatible components to an existing installation as opposed to replacing an entire module. Scalability equals money saved in the long run.

Need help finding the right PLC for your application?

Contact our sales team.

Integrating Micro PLCs With IoT & Industry 4.0

There are plenty of use cases for a micro PLC without sacrificing any features and hardware. With their numerous advantages, these flexible controllers have become increasingly popular in industries such as building automation, remote reboot, and process control. They are a natural fit for capturing data at the edge and a key part of the advancement into Industry 4.0.

These devices often come with built-in communications capabilities, allowing them to connect to the networks or other controllers. This enables remote monitoring and control of automation systems. Users have nearly real-time access to data, remote troubleshooting, and the ability to adjust the control logic without being physically present at the site. Some PLCs, including ours, are cloud-compatible, further expanding the connected ecosystem of automation devices.

With the increasing adoption of Industry 4.0 technologies across industries, the ability of micro PLCs to integrate seamlessly is a significant advantage. They allow integrators to future-proof their automation systems and stay ahead in the era of digital transformation.

Why Choose ControlByWeb® PLCs

The world of industrial automation offers a dizzying number of options when choosing a PLC, relays, sensors, software, and more. It’s important to choose components that will stand the test of time and offer the flexibility to adapt as needs change and systems grow. ControlByWeb PLCs are a great option for their ease of use, robust features, and in-house support. Controllers include an intuitive web-based interface that allows users to quickly set up logic, configure I/O, and monitor the system. Everything we make is designed, sold, and supported in-house at our home office in northern Utah. Our products have been shown to be reliable and secure by nature with decades of use cases across all sorts of industrial applications.

Get in touch with our team or schedule a 15-minute demo to learn more about our relays and see why systems integrators, engineers, and technicians turn to ControlByWeb for their industrial IoT needs.